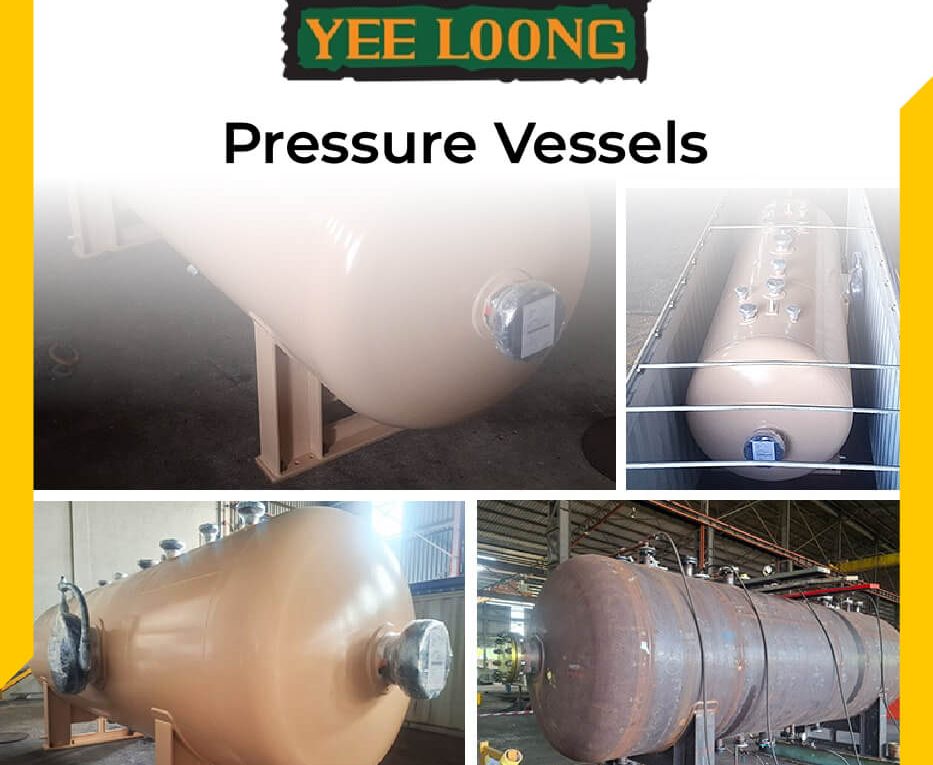

Pressure Vessels Usage & Industrial Needs in Malaysia

Understanding the Role of Pressure Vessels in Malaysia’s Industrial Growth

Pressure vessels are vital components in Malaysia’s industrial landscape. From oil & gas to palm oil processing and chemical manufacturing, these vessels are essential for safely containing gases or liquids under pressure.

A well-designed pressure vessel ensures safety, efficiency, and long-term reliability—making it one of the most critical assets in industrial operations.

As Malaysia continues to expand its manufacturing, energy, and processing sectors, the demand for a trusted pressure vessel manufacturer in Malaysia has become more significant than ever. Companies now seek reliable pressure vessel fabricators that meet strict standards such as ASME, DOSH Malaysia, and international specifications.

What Is a Pressure Vessel?

A pressure vessel is an enclosed steel container designed to store or process fluids (liquids or gases) at high pressure, significantly above or below atmospheric pressure.

These vessels are built to precise standards, ensuring they can handle high stress and extreme temperatures.

Common types of pressure vessels include:

- Air receivers and storage tanks

- Reactors for chemical and petrochemical plants

- Deaerators and steam drums for power generation

- Filter and water softener vessels for water treatment systems

- Shell-and-tube heat exchangers

As a certified pressure vessel fabricator, Yee Loong Engineering focuses on quality fabrication, safe design, and compliance with industrial regulations to ensure consistent performance in demanding conditions.

Industrial Usage of Pressure Vessels in Malaysia

Malaysia’s diverse industries rely on pressure vessels daily. Below are the key sectors where these vessels play a crucial role:

1. Oil & Gas and Petrochemical Plants

Used in refining, gas separation, and chemical reaction processes.

Pressure vessels such as separators, columns, and reactors withstand extreme pressure and heat.

2. Palm Oil and Oleochemical Industries

Malaysia is a global leader in palm oil production.

Pressure vessels are used in deodorisation, fractionation, and heat recovery systems—ensuring product purity and energy efficiency.

3. Food & Beverage Manufacturing

Vessels help process ingredients under hygienic, controlled environments for brewing, fermentation, and blending.

4. Water Treatment & Environmental Systems

Water softeners, filters, and storage vessels operate under pressure to maintain continuous water purification in industrial plants.

5. Power Generation & Energy Sector

Boilers, steam drums, and condensate tanks manage steam and energy transfer within power stations.

These applications demonstrate why choosing a certified pressure vessel manufacturer Malaysia is critical for safety, compliance, and efficiency.

Why Malaysia Is a Hub for Pressure Vessel Manufacturing

Malaysia has developed strong capabilities in custom metal fabrication, welding, and engineering design — making it a regional hub for high-quality pressure vessel production.

Key reasons include:

- Established Industrial Base: Malaysia’s infrastructure supports large-scale fabrication and exports within ASEAN.

- Skilled Engineering Workforce: Local engineers are trained in ASME and DOSH standards.

- Cost-Effective Production: Local manufacturing reduces lead time and logistics costs.

- Strategic Location: Proximity to industrial zones such as Klang Valley, Johor, and Penang enhances delivery and service efficiency.

- Regulatory Compliance: DOSH (Department of Occupational Safety & Health) ensures all pressure vessels meet Malaysia’s safety requirements.

Y L Engineering leverages these national strengths with in-house expertise and advanced fabrication facilities, positioning itself as a trusted pressure vessel manufacturer in Malaysia.

How to Choose the Right Pressure Vessel Fabricator in Malaysia

When sourcing pressure vessels, selecting the right partner ensures long-term reliability and safety. Here’s what to look for:

- Certifications & Standards Compliance

Look for manufacturers with ASME U-Stamp, DOSH, or ISO certifications. - Design & Engineering Capabilities

Custom design tailored to your operating pressure, temperature, and material requirements. - Material Expertise

Experience with carbon steel, stainless steel, and duplex materials for diverse industrial applications. - Quality Control & Testing

Non-destructive testing (NDT), pressure tests, and full documentation to verify quality. - Project Support & Local Presence

Choose a fabricator based in Malaysia for faster support, site installation, and after-sales service.

Y L Engineering offers all these capabilities under one roof — providing turnkey solutions from design to delivery.

The Importance of Heat Exchangers in Malaysia’s Industries

Alongside pressure vessels, heat exchangers are equally essential in Malaysia’s industrial systems.

As a heat exchanger manufacturer Malaysia, Y L Engineering designs and fabricates:

- Shell-and-tube heat exchangers

- Condensers

- Reboilers

- Evaporators

- Economisers

These units are used in oil refineries, palm oil mills, chemical plants, and HVAC systems — improving energy efficiency and thermal management across industries.

By offering both pressure vessel fabrication and heat exchanger manufacturing, Y L Engineering provides clients with integrated process equipment solutions built to international standards.

Trends in Malaysia’s Pressure Vessel Fabrication

The Malaysian market is rapidly evolving with advanced technologies such as:

- Modular Skid Systems – compact, pre-assembled systems for quick plant installation.

- Automation & Precision Welding – ensuring high consistency and reduced human error.

- Sustainable Materials & Coatings – corrosion-resistant materials for longer lifespan.

- Digital Design (CAD / 3D Modeling) – improving fabrication accuracy and documentation.

These trends help Malaysian fabricators deliver world-class quality while maintaining competitive pricing.

Why Choose Yee Loong Engineering Sdn Bhd as Your Pressure Vessel Partner

Y L Engineering Sdn Bhd is a Malaysian-based engineering company specialising in pressure vessel fabrication and heat exchanger manufacturing.

With years of industry experience, the company provides:

- Custom design & fabrication for process industries

- Certified workmanship adhering to ASME & DOSH standards

- Comprehensive testing & inspection before delivery

- Efficient project timelines & responsive support

Yee Loong enginnering services coverage:

- Pressure Vessels

- Heat Exchangers / Air Cooled Heat Exchangers

- Flare Stacks / Stacks

- Furnaces / Kilns / Burners

- Storage Tanks

- Process Skids / Piping Works

- Mechanical Steelworks

- Structural Steelworks

Whether you need a pressure vessel manufacturer Malaysia for petrochemical use or a heat exchanger manufacturer Malaysia for industrial cooling systems, Y L Engineering delivers dependable engineering solutions trusted by clients nationwide.